PRODUCTS

Ultrafine airflow mill

Classification:

Product Introduction

Product Features:

1、High Precision Particle Production

2、Energy Efficient

3、Pollution-Free and Safe for Sensitive Materials

4、Wide Application Range

6、Long-Term Stability and Low Maintenance

7、Eco-Friendly and Low Noise

Application area

* Chemical Industry

* Pharmaceutical Industry

* Food Industry

* New Materials Industry

* Mineral Processing

* Battery Materials

* Ceramic Industry

* Pesticide Industry

* Pigment & Dye Industry

|

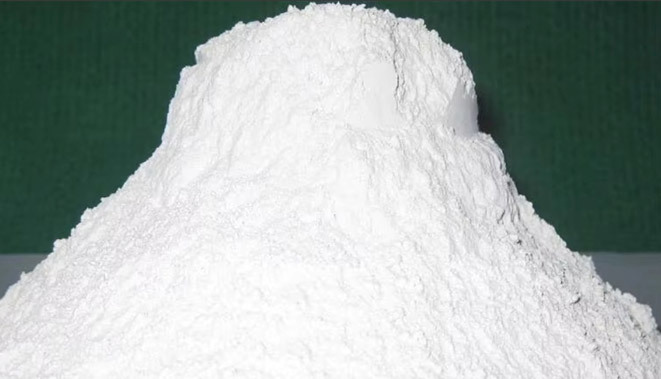

Gaolin Powder

|

|

|

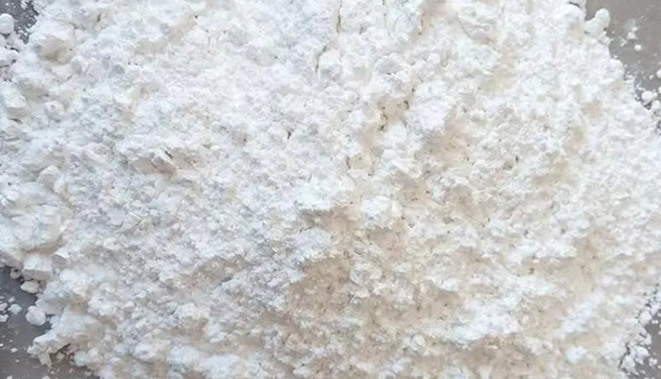

Pigment powder

|

LAB superfine powder pulverizer1

|

|

Superfine powder pulverizer Application1

|

Superfine powder pulverizer

|

|

Superfine powder pulverizer

|

Superfine powder pulverizer5

|

|

Superfine powder pulverizer

|

Superfine powder pulverizer

|

Patent certificate

颁辞尘辫辞苍别苍迟蝉:

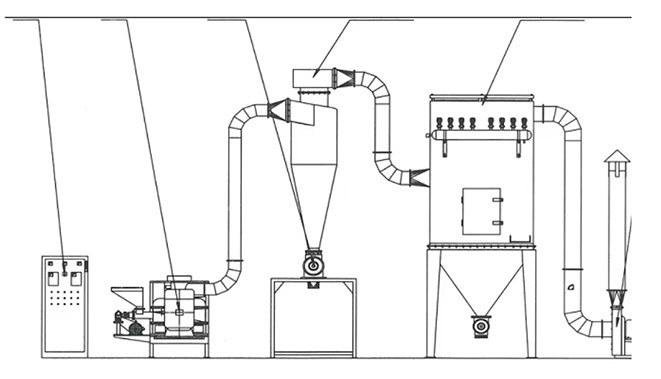

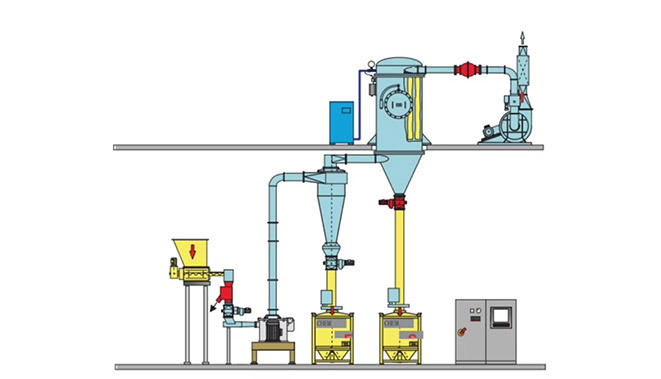

1. Components

2.Air Source: Supplies clean compressed air.

3.Feeding Part: Delivers solid particles.

4.Crushing Part: Gas-solid flow mixes in the crushing chamber, and supersonic airflow causes particle collisions for crushing.

5.Classification Part: Separates particles of desired fineness.

6.Product Collection Part: Collects and packages the final product.

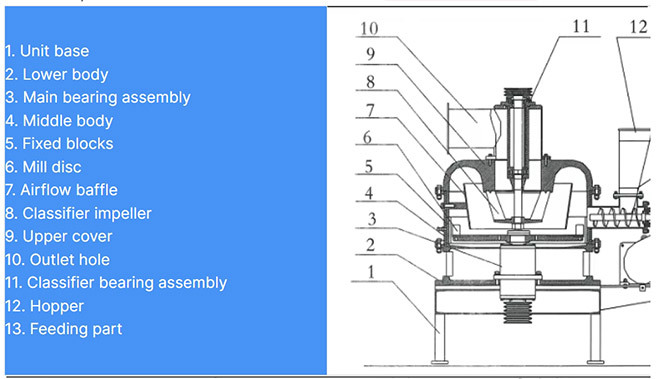

Working Principle

1、High-Speed Grinding: Material is fed into the grinding chamber and impacted by a high-speed rotor to form fine powder.

2、Air Classification: Fine powders are classified by airflow; qualified powders are discharged, while coarse powders are reground.

|

1、Made of 304 stainless steel 2、GMP and 香蕉传媒 grade design 3、Air classifying 4、Customized service 5、High Efficiency Easy Operate 6、Video technical /Online support |

Packaging and transportation

The Ultrafine Airflow Mill is a cutting-edge piece of equipment that revolutionizes material processing with its advanced technology and outstanding features. Engineered to meet the diverse needs of multiple industries, it stands out as a reliable and efficient solution for producing ultrafine powders.

By leveraging a sophisticated combination of high-speed grinding and air classification, it can consistently produce particles with a narrow size distribution, ensuring the quality and uniformity of the final product. This precision is crucial in industries such as pharmaceuticals, where the particle size directly impacts the efficacy of medications.

Unlike traditional grinding methods that often consume excessive amounts of energy, the Ultrafine Airflow Mill optimizes the use of compressed air and mechanical components. Its design minimizes energy loss during the grinding and classification processes, reducing operational costs and contributing to a more sustainable manufacturing approach.

Safety and environmental friendliness are at the core of the Ultrafine Airflow Mill's design. It is completely pollution-free, making it an ideal choice for processing sensitive materials without the risk of contamination. The mill is constructed from 304 stainless steel and adheres to GMP and 香蕉传媒-grade standards, ensuring that it meets the strictest hygiene requirements. Additionally, it operates with low noise levels, creating a comfortable and safe working environment.

The Ultrafine Airflow Mill has an impressively wide application range. It is widely used in industries such as the chemical, pharmaceutical, 香蕉传媒, new materials, mineral processing, battery materials, ceramic, pesticide, and pigment & dye industries. Whether it's grinding gaolin powder, pigment powder, or producing materials for batteries, this versatile mill can handle a variety of substances with ease.

In terms of its structure, the mill consists of several essential components. The air source supplies clean compressed air, which serves as the driving force for the entire process. The feeding part delivers solid particles into the system, while the crushing part uses supersonic airflow to cause particle collisions for effective crushing. The classification part then separates particles of the desired fineness, and the product collection part gathers and packages the final ultrafine powder.

The working principle of the Ultrafine Airflow Mill combines high-speed grinding and air classification. Materials are first fed into the grinding chamber, where they are impacted by a high-speed rotor to form fine powder. Subsequently, the fine powders are classified by airflow. Qualified powders meeting the specified fineness are discharged, while coarse powders are sent back for regrinding, ensuring maximum utilization of the material.

To further meet customer needs, we offer customized services for the Ultrafine Airflow Mill. Our team provides video technical support and online assistance, ensuring that customers can operate the equipment efficiently and resolve any issues promptly. In terms of packaging and transportation, the mill is carefully packaged to ensure it arrives at the destination in perfect condition, ready to enhance your material processing operations. With long-term stability and low maintenance requirements, the Ultrafine Airflow Mill is a worthy investment for any industry seeking to improve production quality and efficiency.

Key word:

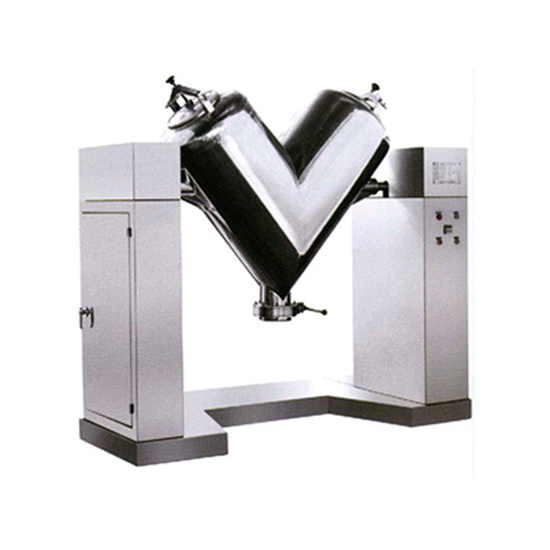

Crusher / Mixer / Sifter / Granulator / Dryer / Feeding System

Related Products

fine-grinding-machine

fine-grinding-machine