NEWS

Transform Production Line with Tablet Deduster Machines

Oct 03,2024

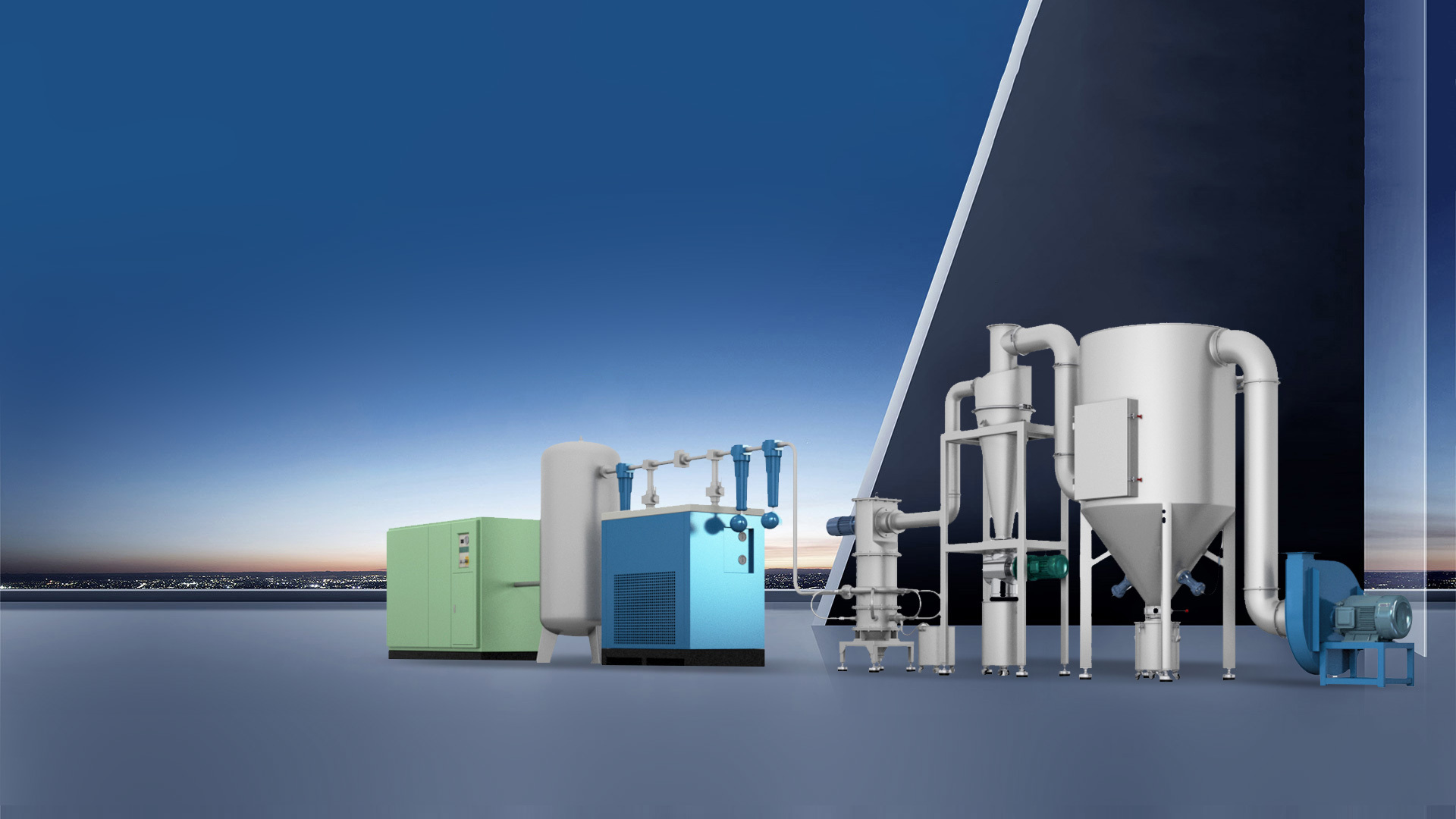

Revolutionize Your Dust Removal Process with Cutting-Edge Tablet Deduster Machine

Introduction to Tablet Dduster Machines

In today's fast-paced manufacturing environment, maintaining cleanliness is crucial for operational efficiency. The tablet deduster machine emerges as an essential tool, ensuring that your production line remains free from excess dust and contaminants. This guide explores the innovative features and advantages of using a tablet deduster machine, helping you make informed decisions to enhance your manufacturing processes.

What is a Tablet Deduster Machine?

A tablet deduster machine is a specialized device designed to remove dust and fines from tablet surfaces before packaging. These machines are commonly used in pharmaceutical, nutraceutical, and 香蕉传媒 industries, where product purity and quality are paramount. By utilizing vibration and airflow, tablet dedusters efficiently eliminate unwanted particles, ensuring a clean and high-quality product.

Types of Tablet Deduster Machines

There are several types of tablet deduster machines, including:

- Vibratory Dedusters: These rely on vibration to shake off dust from the tablet surface.

- Airflow Dedusters: These use directed air streams to blow away dust particles.

- Combination Dedusters: These machines integrate both vibration and airflow for optimal dust removal.

The Importance of Dust Removal in Manufacturing

Dust removal is a critical aspect of manufacturing operations. Excess dust can lead to various issues, including:

- Product Contamination: Dust can compromise the purity of the product, leading to quality control failures.

- Equipment Damage: Dust accumulation can wear down machinery, leading to increased maintenance costs and downtime.

- Safety Hazards: Dust in the workplace poses inhalation risks for employees and can increase fire hazards.

By implementing effective dust removal solutions like tablet deduster machines, manufacturers can significantly reduce these risks and enhance overall productivity.

How Tablet Deduster Machines Work

Tablet deduster machines operate through a combination of mechanical vibration and pneumatic airflows. The process typically involves the following steps:

1. Feeding Mechanism: Tablets are fed into the deduster machine via a hopper or conveyor.

2. Vibration: The machine vibrates to shake off any loose dust and fines from the tablet surfaces.

3. Airflow: Simultaneously, directed air is blown through the tablet bed, further removing residual dust particles.

4. Collection: The removed dust is collected in a designated container or expelled through a dust extraction system.

This dual-action ensures thorough dust removal while minimizing damage to the tablets.

Benefits of Using a Tablet Deduster Machine

Integrating a tablet deduster machine into your production line offers numerous benefits:

1. Enhanced Product Quality

By removing dust and contaminants, tablet dedusters help maintain the integrity of your products, leading to higher quality and customer satisfaction.

2. Improved Operational Efficiency

With effective dust removal, manufacturers can reduce downtime caused by equipment maintenance and product recalls, leading to smoother operations.

3. Cost-Effectiveness

Investing in a tablet deduster machine can save costs associated with product waste, rework, and equipment repairs.

4. Compliance with Industry Standards

Adhering to cleanliness and safety regulations is crucial in the manufacturing industry. Tablet dedusters help ensure compliance with standards such as Good Manufacturing Practices (GMP).

5. Versatility

These machines can be used for various tablet sizes and formulations, providing flexibility across different production lines.

Key Features to Consider When Buying a Tablet Deduster Machine

When selecting a tablet deduster machine, consider the following features:

1. Size and Capacity

Choose a machine that fits your production scale. Larger operations may require high-capacity machines that can handle significant throughput.

2. Customization Options

Look for machines that offer customizable settings for vibration intensity and airflow to accommodate different tablet types and formulations.

3. Ease of Cleaning

Select a machine designed for easy disassembly and cleaning to ensure compliance with hygiene standards.

4. Durability and Build Quality

Invest in a machine made from high-quality materials to withstand the rigors of daily use in a manufacturing environment.

5. Safety Features

Safety should be a priority. Ensure the machine has built-in safety features to protect operators and prevent accidents.

Best Practices for Using Tablet Deduster Machines

To maximize the effectiveness of your tablet deduster machine, follow these best practices:

1. Regular Maintenance

Implement a routine maintenance schedule to ensure the machine operates at peak performance and longevity.

2. Train Operators

Provide comprehensive training for operators to ensure they understand how to use the machine efficiently and safely.

3. Monitor Performance

Keep track of the machine’s performance metrics to identify any issues early and address them promptly.

4. Optimize Settings

Adjust the vibration and airflow settings based on the specific tablet formulation for optimal dust removal efficiency.

5. Perform Regular Quality Checks

Conduct regular inspections and quality checks on finished products to ensure they meet the required cleanliness standards.

Conclusion

Investing in a cutting-edge tablet deduster machine can significantly enhance your manufacturing process by ensuring high product quality, reducing operational costs, and maintaining compliance with industry regulations. By understanding how these machines work and implementing best practices, you can revolutionize your dust removal processes, paving the way for a more efficient and cleaner production environment. Embrace the future of manufacturing with our tablet deduster solutions, and watch your operations soar to new heights.

More News