NEWS

Understanding the Role of Dedusting Equipment in Industrial Air Quality Management

Oct 10,2024

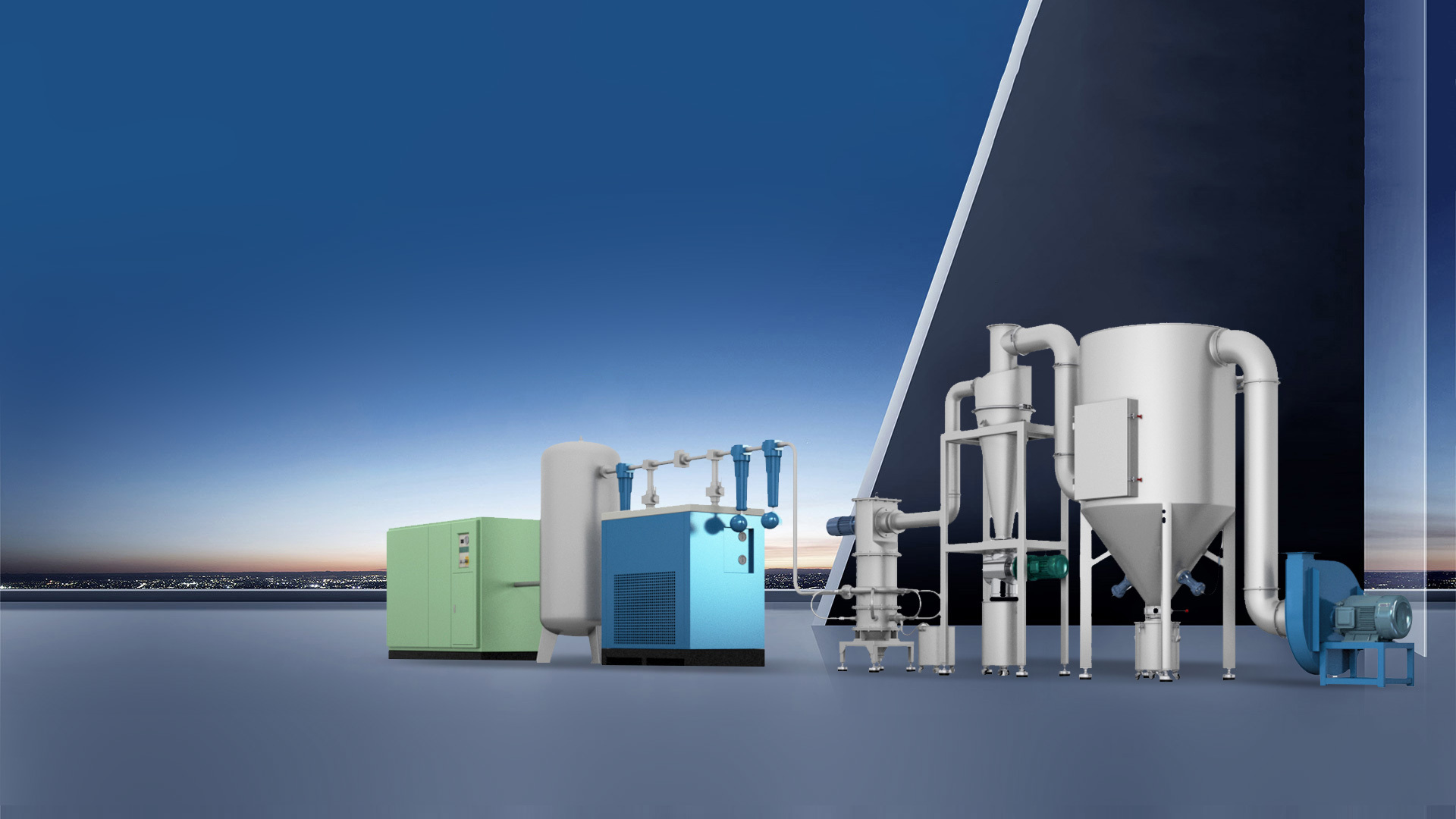

In the realm of industrial operations, maintaining air quality is a crucial aspect that directly influences both worker safety and equipment efficiency. This is where dedusting equipment factories play a pivotal role. Dedusting systems are designed to remove airborne particulates and contaminants generated during manufacturing processes, ensuring that the air remains clean and safe for workers and the environment.

Dedusting equipment serves multiple purposes within industrial facilities. Primarily, it helps to reduce the concentration of hazardous dust particles in the air, which can lead to respiratory issues and other health problems for employees. By implementing efficient dedusting solutions, factories can comply with health and safety regulations, thereby fostering a safer workplace.

The designs of dedusting systems vary significantly based on the specific requirements of an industry. Common types include baghouse filters, electrostatic precipitators, and cyclones. Baghouse filters, for instance, utilize fabric filter bags to capture dust particles, while electrostatic precipitators employ high-voltage charges to collect contaminants. Cyclones, on the other hand, utilize centrifugal force to separate heavier particles from the air stream. Each type has unique advantages and can be tailored to meet the specific needs of a facility.

Furthermore, the integration of advanced technologies such as automated controls and real-time monitoring systems has revolutionized the effectiveness of dedusting equipment. These innovations allow for continuous assessment of air quality, enabling facilities to respond proactively to fluctuations in dust concentration. Such systems not only enhance operational efficiency but also minimize maintenance costs by providing timely alerts for filter replacements or repairs.

When selecting dedusting equipment for a factory, it is essential to consider factors such as the type of dust being generated, the volume of air that needs to be treated, and the overall layout of the facility. Engaging with experienced professionals during the selection process can lead to more informed decisions, ensuring that the dedusting system aligns with both operational goals and environmental standards.

Dedusting equipment factories contribute significantly to improving industrial air quality by providing effective solutions for dust management. By understanding the various types of dedusting systems and their operational benefits, businesses can optimize their processes and create a healthier work environment. As industries continue to evolve, the importance of maintaining clean air through advanced dedusting technologies will only grow, making it an essential component of modern manufacturing practices.

More News